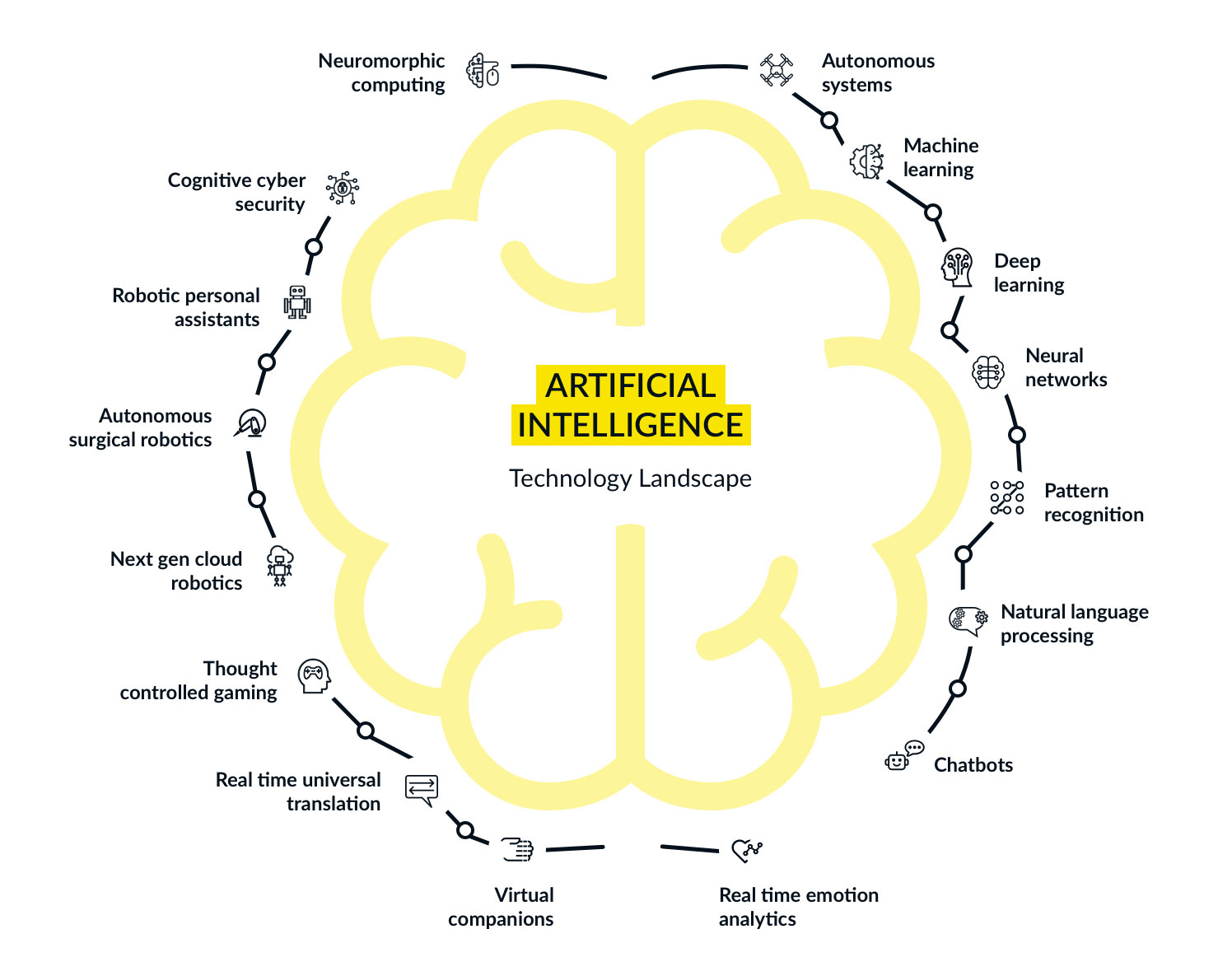

Why should we choose the AI path for the future of APM? Because the system of the future is going to be proactive and not just reactive. This could be possible through a more predictive and connected system that learns from its past and. Any industrial setup of the future would endeavor to achieve the following advantages that are possible through the integration of an AI tool:

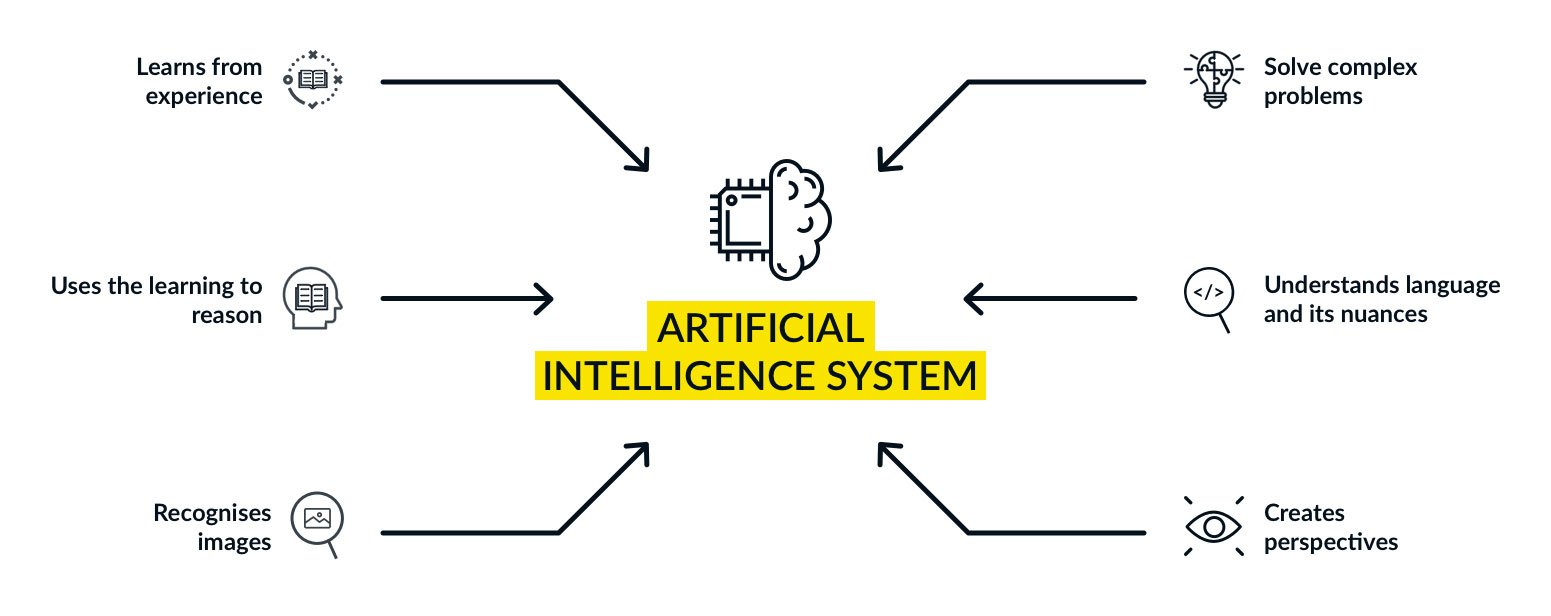

- Minimal errors in execution: There is negligible human intervention required at crucial steps of implementation and maintenance. The system itself plays the role of an expert. It learns from humans, across a vast connected network, and then makes its own decisions based on the highest probable success ratio.

- Lower effective costs: Through the reduction of efforts, which would have been wasted in trying out various methods to fix a problem, the overall effective costs of production are brought down significantly. This means lower overheads and higher profit margins.

- Lower operational risks for humans: Many accidents happen due to operational hazards for human workers on a plant. Similar risks may apply to parts of adjacent assets as well in case of an accident. This can cause much damage to life, property, business, and revenue. AI can create a safer work environment by putting smart connected devices to do regular maintenance checks. It eliminates the need for a manual inspection, which may be highly risky if the assets are failing. Also, it allows a higher preparation time through predictive analysis to fix the device, which has a probability of failure in the coming future.

- Automation of frequent tasks: There are several mundane tasks on a plant that have low demands for expertise but need to be accomplished in a limited time. Such tasks can easily be identified, scheduled, delegated, and managed by an intelligent system.

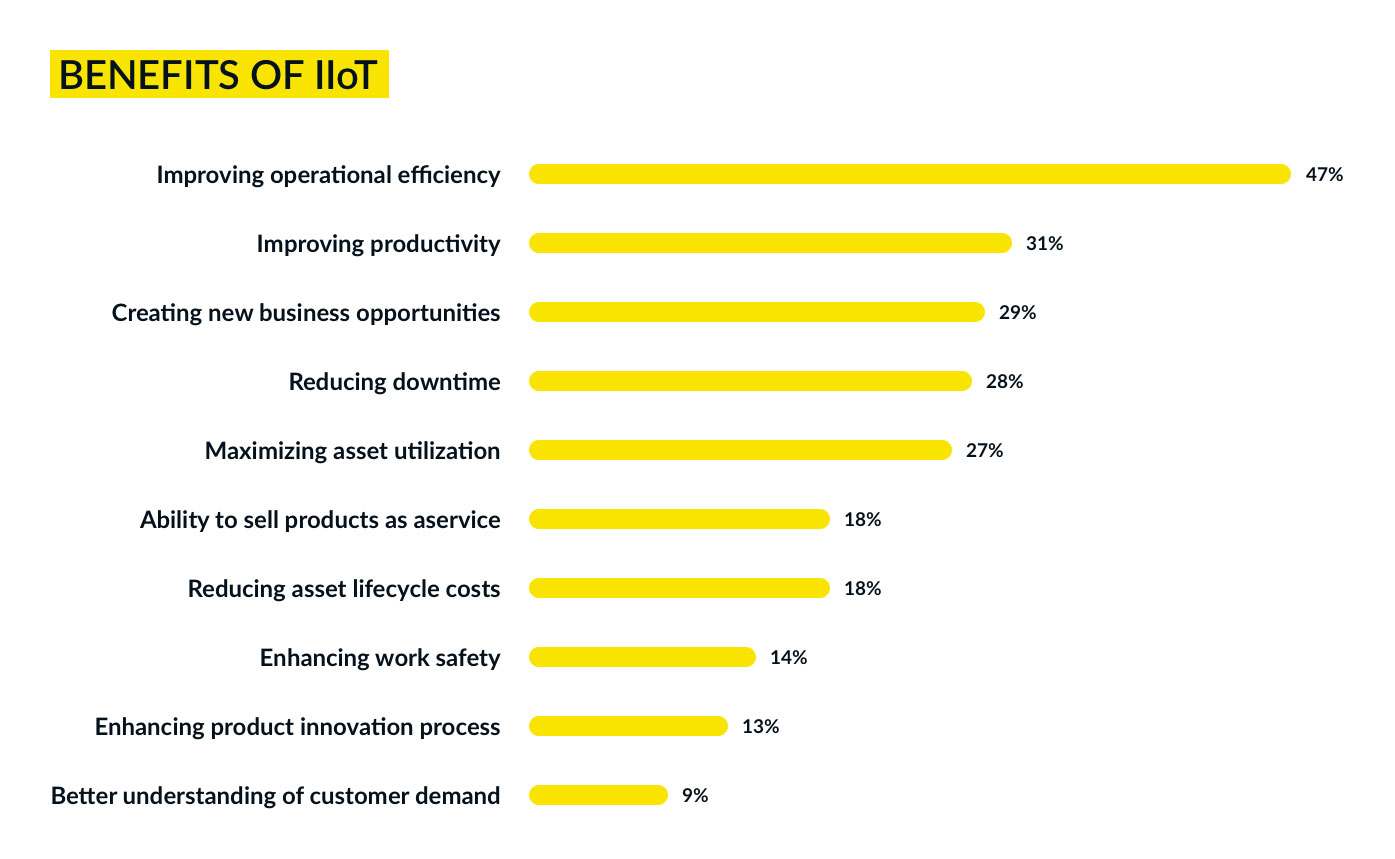

- Higher productivity: Lower failure rate implies reduced downtimes and higher productivity. AI systems, when properly designed and implemented, could bring a high efficiency into the processes, which supports bigger profits.

- Enhanced throughput: With control over the entire process flow, artificial intelligence can identify patterns and plan each activity with absolute precision. Optimized resource and process utilization Through a connected network, an AI system has clear visibility of resource availability and requirement. It can automatically delegate the pending tasks to the idle resources, without any need for manual intervention. This enhances the efficiency and efficacy of the system manifold.

- Proactive identification of threats: It can offer a fail-safe environment where the possible failures are detected, and all relevant risks are mitigated before they happen, through predictive analytics.

- Simplest possible resolutions: With a system that analyses the probable answers to various problems on several practical parameters, the solution chosen is often the most straightforward possible for a given scenario. This intervention saves a lot of time and effort, and in turn, checks a lot of revenue loss for the plant owners.

- Zero Constraints: With the artificial intelligence system taking the center stage through the Industrial Internet of Things (IIoT), the possible limitations that may arise due to the size of the plant, geographic location, and communication barriers are all taken care of. It acts as a binding force for the entire network, which is accessible to each node for better assessment and analysis. In turn, it converts the system into a transparent entity which has accessible information shared with all the nodes, so that it may be utilized as needed.

WHERE CAN IT GO WRONG?

There are two essential checkpoints which must be considered in this regard:

- Error Handling:

Yes, there will be errors. A self-learning AI platform may take a little longer than expected to acclimatize and mature in a particular environment. The entire system should preferably make suitable back-doors available for human monitoring and intervention in its nascent stages. These interventions serve as a benchmark for future decisions by the system, thereby reducing the dependency on humans as time goes by.

- Building and keeping the trust (of users):

The system is of utility if and only if it is capable of establishing a trust factor with its users. When dealing with critical data about enterprise assets, it becomes imperative to ensure the high credibility of the system. Any possible instance which might result in an irreparable error is enough to break all trust in the system, thereby rendering it useless.

A well planned and designed transition from a conventional system to an artificially intelligent system can save much trouble and unnecessary expenses. The ‘Subject Matter Expert’ must work in collaboration with a ‘Designer’ who understands the users’ expectations. This team can undertake detailed research and prepare a list of following items before planning the transition:

- Possible scenarios and use cases where the user intervention is required for each user role

- Possible causes of failure and their relevant impacts

- Exact benchmarks that need to be ensured to assess the success of the system, failing which a human intervention may be provided

- Available timelines and priorities as per the company roadmap

Once these lists are available, the transition plan can be charted out, based on risk vs. importance. The first priority is given to the low risk and high importance use cases, and so on. It should be noted that based on the relevant performance markers of the system, the human intervention hierarchy and its protocols need to elaborately defined and communicated to all concerned users.

Artificial intelligence is the future, and let’s acknowledge the fact that it is inevitable and unstoppable. Having known this, let’s embrace it as a friend and prepare to welcome it. The challenges that may come along the way are still under speculation, as would hold true for any innovative idea.

But as they say, “Future is built from the future, not from the past”, we too must accept it as a breakthrough which has the potential to make the world a better and safer place.

“Everything we love about civilization is a product of intelligence, so amplifying our human intelligence with artificial intelligence has the potential of helping civilization flourish like never before – as long as we manage to keep the technology beneficial.”